Ngwaahịa

eriri eriri igwe anaghị agba nchara ma ọ bụ waya dị n'ime isi ihe na-eduzi maka textiles na-ekpo ọkụ

Nkọwa ngwaahịa

1 - eriri eriri igwe anaghị agba nchara ebe dayameta nke eriri onye ọ bụla bụ 12µ ma ọ bụ 14µ. Ọnụ ọgụgụ nke eriri na-adịkarị site na gburugburu 200 ruo ihe karịrị 1500 filaments. Nke a na-enye gị ogologo ndụ nke kacha 'kachasị mma na klaasị'. N'ihi eriri ndị dị mma ejiri, eriri ndị a ka na-adị gịrịgịrị na dayameta zuru oke ma si otú a na-agbanwe agbanwe na nhazi.

2-Anyị na-ekpuchi ọtụtụ ụdị nkwụsi ike dị ala karịa waya dị mma na micro cables nwere àgwà na-adịgide adịgide ma na-agbanwe agbanwe, nke pụrụ iche anyị nwere eriri micro cables dị n'ime ime nwere ike ịkọwa nguzogide n'otu mita ị chọrọ ma na-enyekwu mgbanwe na imewe ma ka na-enye nke ka mma. flex-ndụ karịa ụdị Cu-cables. Dabere na alloy kechie mpụta nke nwere ike tinned, ọla kọpa, ọla ọcha wdg, anyị nwere ike mepụta ihe na-eguzogide ọgwụ ọbụlagodi 1 ohm / m micro cables site na otu na agbadoro ụdị dị ka ndị ahịa chọrọ.

Uru micro cables dị n'ime ime akwa

Na-ehulata Nguzogide

N'ihi nhazi na nchikota nke ihe, waya nwere ihe magburu onwe ekwe nguzogide.

Mgbanwe

Igwe eriri micro na-eji foil metal dị gịrịgịrị dị ka onye nduzi, nke na-achọpụta mgbanwe dị ukwuu.

Ultra-mma

Mgbe extrusion anyị micro cable nke kachasi nwere ike ịbụ 0.35mm.

Ike Tensile dị elu

Anyị na-eji Aramid / Liquid Crystal Polymer fibers na onye injinia elu teknụzụ dị elu.

Okpomọkụ dị elu. Nguzogide

Anyị na-eji eriri aramid ma ọ bụ igwe anaghị agba nchara maka eriri, oke okpomọkụ na-eguzogide site na ogo 230 ruo 580 maka nhọrọ gị.

Emecha & mkpuchi

N'ụwa gị, a na-enwekarị mkpa maka onye ọ bụla lacquering nke filaments ma ọ bụ mkpuchi extrusion n'ozuzu n'elu eriri zuru ezu. Anyị nwekwara ike ime nke ahụ, ọdịnaya extrusion anyị gụnyere FEP, PFA, PTFE, TPU wdg.

Nkọwa jaketị mkpuchi

| Extrusion | TPE | FEP | MFA |

| Melting Point | 205°C | 255°C | 250°C |

| Cna-arụ ọrụ Teze ukwu | 165°C | 205°C | 225°C |

Ngwunye eriri igwe anaghị agba nchara

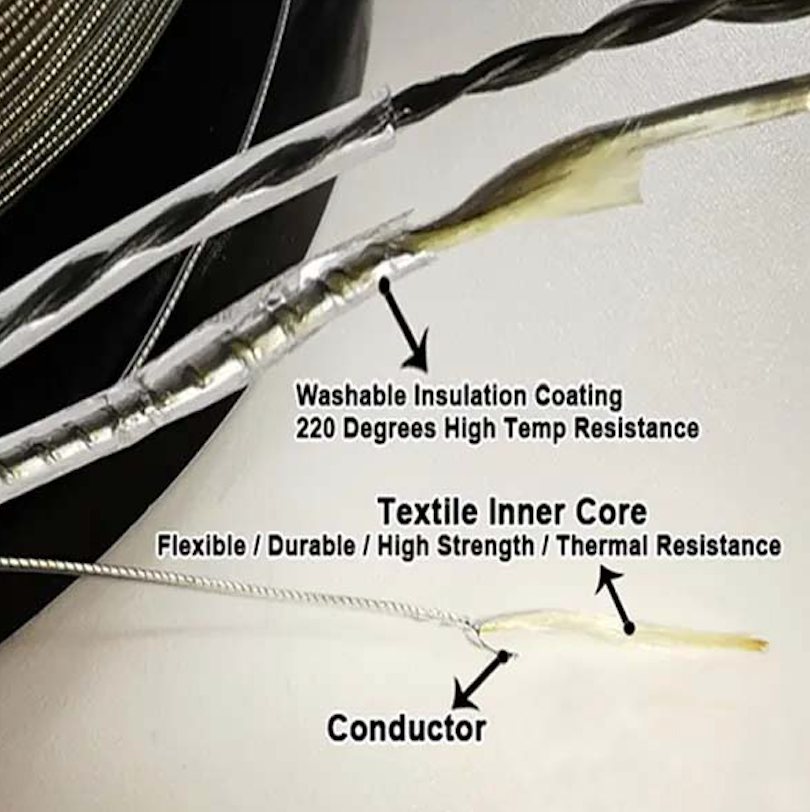

Ihe nrụpụta Micro USB Textile Inner Core

Ngwa kpo oku gbadoro ụkwụ

Igwe anaghị agba nchara na-ejikọta oke nguzogide dị iche iche maka ntụaka gị.

| Dayameta (um) | Filaments | Ike (cN) | Ibu (g/m) | Mgbatị (%) | Ịrụ ọrụ (Ohm/m) |

| 8 | 1000F x 1 | 69 | 0,420 | 1.10 | 16 |

| 8 | 1000F x 2 | 108 | 0,850 | 1.10 | 8 |

| 12 | 100F x 1 | 24 | 0.110 | 1.10 | 59 |

| 12 | 100F x 2 | 41 | 0.190 | 1.10 | 38 |

| 12 | 100F x 3 | 69 | 0.280 | 1.10 | 22 |

| 12 | 257F x 1 | 59 | 0.260 | 1.10 | 27 |

| 12 | 275F x 2 | 75 | 0,540 | 1.10 | 14 |

| 12 | 275F x 3 | 125 | 0,780 | 1.10 | 9 |

| 12 | 275F x 4 | 130 | 1.050 | 1.10 | 7 |

| 12 | 275F x 5 | 160 | 1.300 | 1.10 | 5 |

| 12 | 275F x 6 | 180 | 1.500 | 1.10 | 4 |

| 12 | 1000F x 1 | 100 | 0,950 | 1.10 | 7 |

| 12 | 1000F x 2 | 340 | 1.900 | 1.10 | 4 |

| 14 | 90F x 2 | 46 | 0.190 | 1.10 | 44 |

| 14 | 90F x 1 | 25 | 0.110 | 1.10 |

Waya n'ime ime textile dị iche iche na-eguzogide

| Onye nduzi n'èzí | Textile Inner Core | Dayameta mm | Omume omume ≤Ω/m |

| Ọla kọpa 0.08mm | 250D Poyester | 0.20± 0.02 | 6.50 |

| Ọla kọpa 0.10mm | Polyester 250D | 0.23± 0.02 | 3.90 |

| Ọla kọpa 0.05mm | 50D Kuraray | 0.10± 0.02 | 12.30 |

| Ọla kọpa 0.1mm | 200D Dinima | 0.22± 0.02 | 4.00 |

| Ọla kọpa 0.1mm | Polyester 250D | 1*2/0.28 | 2.00 |

| Ọla kọpa 0.1mm | 200D Kevlar | 0.22± 0.02 | 4.00 |

| Ọla kọpa 0.05mm | Polyester 50D | 1 * 2/0.13 | 8.50 |

| Ọla kọpa 0.05mm | Polyester 70D | 0.11 ± 0.02 | 12.50 |

| Ọla kọpa 0.55mm | Polyester 70D | 0.12 ± 0.02 | 12.30 |

| Ọla kọpa 0.10mm | Owu 42S/2 | 0.27± 0.03 | 4.20 |

| Ọla kọpa 0.09mm | Polyester 150D | 0.19± 0.02 | 5.50 |

| Ọla kọpa 0.06mm | Polyester 150D | 0.19± 0.02 | 12.50 |

| Tin ọla kọpa 0.085mm | 100D Kuraray | 0.17± 0.02 | 5.00 |

| Tin ọla kọpa 0.08mm | 130D Kevlar | 0.17± 0.02 | 6.60 |

| Tin ọla kọpa 0.06mm | 130D Kevlar | 0.16± 0.02 | 12.50 |

| Tin ọla kọpa 0.10mm | Polyester 250D | 0.23± 0.02 | 4.00 |

| Tin ọla kọpa 0.06mm | Polyester 150D | 0.16± 0.02 | 11.6 |

| Tin ọla kọpa 0.085mm | 200D Kevlar | 0.19± 0.02 | 5.00 |

| Tin ọla kọpa 0.085mm | Polyester 150D | 0.19± 0.02 | 6.00 |

| ọla kọpa ọla ọcha 0.10mm | Polyester 250D | 0.23± 0.02 | 3.90 |